在塑膜功能改性母料过去四分之一世纪的耕耘中,精良人坚守“创新为笔、品质为墨”原则,与客户共同书写了“莫(膜)大篇章”。坚实的专业基础,从薄膜开发领先阵营投入到功能母料开发,我们依旧珍视市场上的每一项需求,积极参与新应用场景的每一个开拓。精良人从不停止反省,从不放弃与时俱进的学习能力提升,从不放弃工作能力的提高。

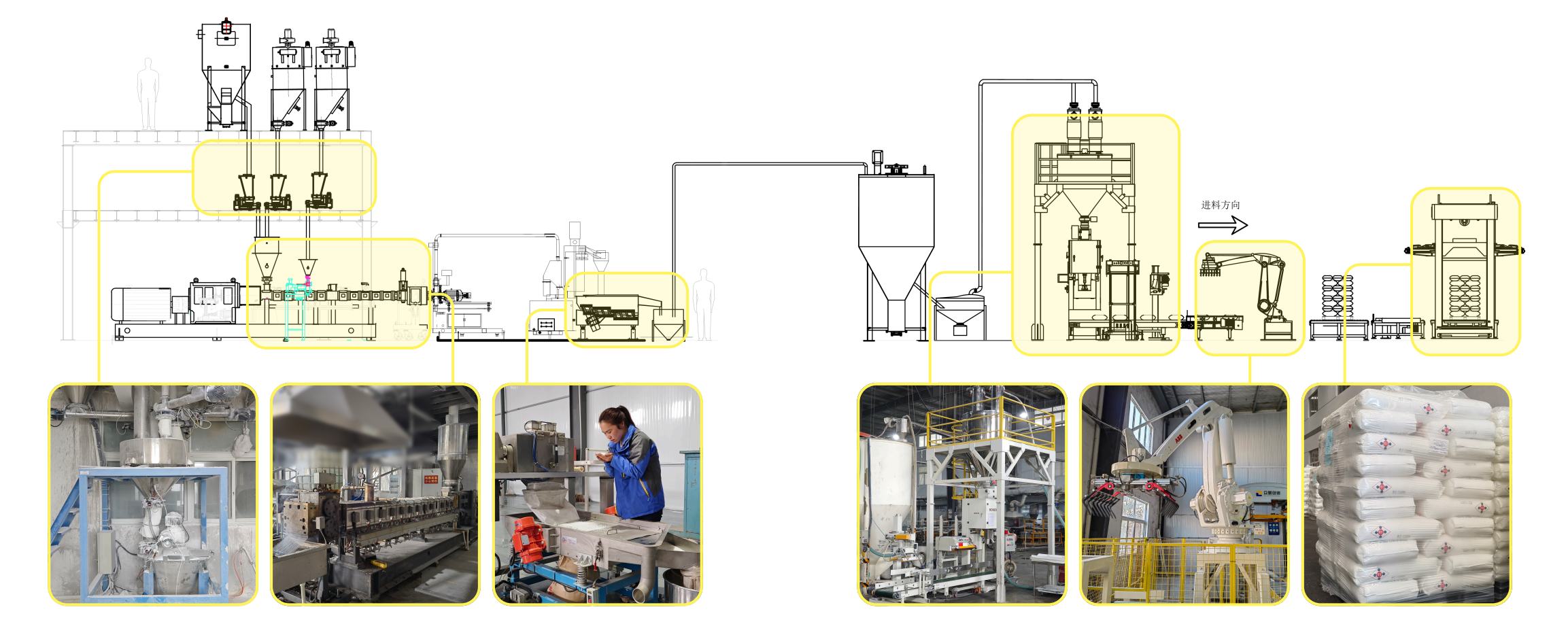

从一条线到十五条产线,从人工计量到自动称重,从购买混配挤出机到设计定制混配工程技术解决方案,成品包装从手工封口到自动包装,从只有一台熔指仪到自有超过三百万价值的现代化恒温恒湿多个检测中心和成套检验装备。

品质的保障建立在对源头、过程、终端等全过程全方位全员每一个细节的可验证、可重复,程序化、标准化掌控。

以下是公司“技研中心”自备的检测装备,我们还有大量的外协科研、检测中心在合作中。

3D Laser Scanning Microscope

DSC Differential Scanning Calorimeter

Infrared Spectrometer (FTIR)

Moisture Analyzer

Capillary Melting Point Tester

Volatile Content Tester

Microscopic Melting Point Apparatus

Melt Flow Index Tester (MFI)

Surface Roughness Tester

Haze & Transparency Tester

Coefficient of Friction Tester

Electronic Tensile Testing Machine

Thermal Drying Oven

Equipped with imported twin-screw extrusion systems from Germany and Japan, combined with fully automated dosing systems, enabling fully automated production from raw material pre-mixing to pelletizing and packaging. This ensures excellent batch consistency with an annual production capacity of 30,000 tons.

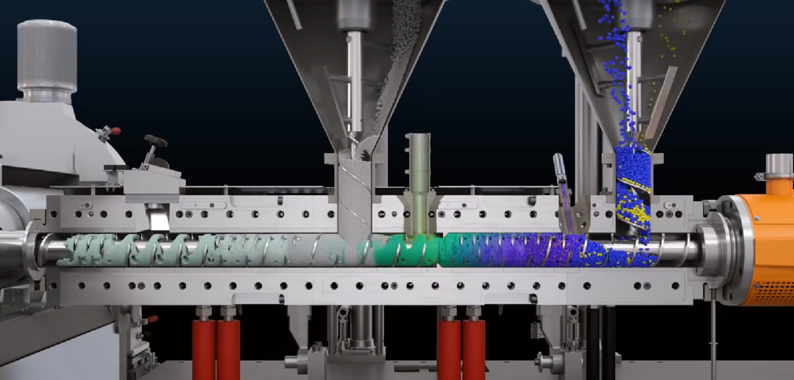

| Four Development Stages of Fine Particle Dispersion Technology | |||

|---|---|---|---|

| Stage | Compounding Equipment & Technical Features | Metering | Pelletizing Technology |

| First Generation | Two-roll mill and internal mixer for pre-mixing and crushing, single-screw or twin-screw compounding, two-step process | Batch | Water-cooled strand pelletizing |

| Second Generation | Twin-screw compounding | Batch | Water-cooled strand pelletizing, water-ring hot cutting, underwater pelletizing |

| Third Generation | High-speed, high-torque twin-screw and reciprocating screw compounding | Batch or Continuous | Water-cooled strand pelletizing, underwater pelletizing |

| Fourth Generation | New proprietary three-dimensional compounding technology — independently developed by Jingliang | Continuous automatic weighing | Underwater pelletizing with high-efficiency drying |