精良高分子CHINAPLAS 2026 展位1.2B86已经确定,期待约见上海之春!

我们诚挚邀请您参加2026年4月21 - 24日在上海·国家会展中心(虹桥)举办的第三十八届“CHINAPLAS国际橡塑展”,在这场顶尖国际平台上,我们会呈现新的功能母料,并期待与您在这“卷”到天际的时代里,共同探寻紧密合作,共创新历史!热忱期待您的光临!

December 14, 2025

Jiangsu Jingliang Polymer Materials Co., Ltd. is a National High-Tech Enterprise and a “Specialized, Sophisticated, Distinctive and Innovative” SME of Jiangsu Province. We focus on the research, development, production, and sales of multifunctional plastic masterbatches and modified materials, and are committed to becoming a global source and solution provider for plastic packaging technologies. With over 20 years of industry experience and ISO 9001 certification, we professionally supply a full range of functional masterbatches including BOPP, BOPE, CPP, and POF.

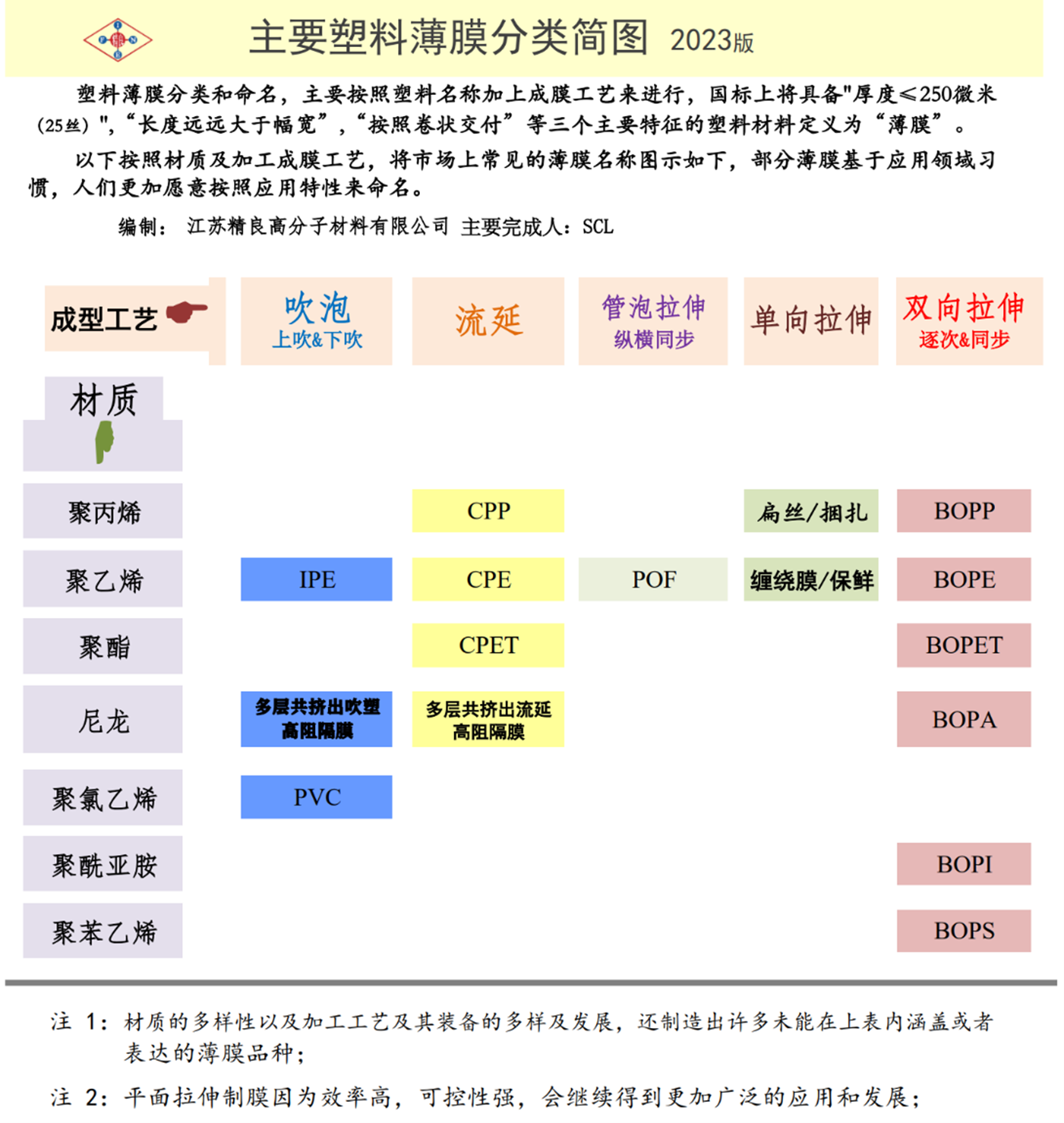

Plastic films are widely used in daily life, industrial production, and recreational activities. Plastic films are manufactured through flat-film and tubular-film processes, in which heat and mechanical force are applied to thermoplastic materials to form films. After decades of development, PE and PP have become the most widely used materials for film manufacturing.

During both the film manufacturing process and the application of finished films, specific physical and mechanical performance requirements are often imposed. These requirements frequently exceed the inherent properties of base materials and the performance limits of processing equipment. To meet such demands, it is necessary to pre-add appropriate and selected functional modification masterbatches (also known as additives) into the anticipated core or surface layers during film production. The design and development of these additive masterbatches to achieve targeted performance improvements is precisely the expertise of the Jingliang team.

Plastic film modification is a field that demands continuous refinement, with increasingly diverse and specialized application scenarios. Like our peers in the film industry, Jingliang remains focused on emerging needs, constantly overcoming technical challenges while maintaining consistent quality and introducing new solutions and products. With sincerity, professionalism, diligence, and a commitment to continuous learning, we strive to maintain excellence and apply it to every collaboration with our customers. Our comprehensive management system and complete testing facilities embody the Jingliang team’s core strengths of “structured innovation, robust quality control, and thorough testing,” enabling us to innovate together and achieve high-quality development.

Jingliang’s products mainly consist of functional modification masterbatches used in polyolefin film applications. These masterbatches are typically named according to their functional characteristics combined with the carrier material. In line with industry conventions and logical classification, we have organized these masterbatches in the “Products & Services” section. Below is a selection of representative functional masterbatch samples and images of their finished packaging forms:

The wide variety of plastic films available today are often endowed with special properties and specific names through the use of functional masterbatches. Below are several application examples demonstrating how functional masterbatches are used in plastic film products:

Serving governments, industrial parks, enterprises, and the public, this open dual-carbon exploration space is built around China’s national strategy of “Carbon Peak · Carbon Neutrality”, integrating policy education, digital carbon management, and low-carbon lifestyle experiences.